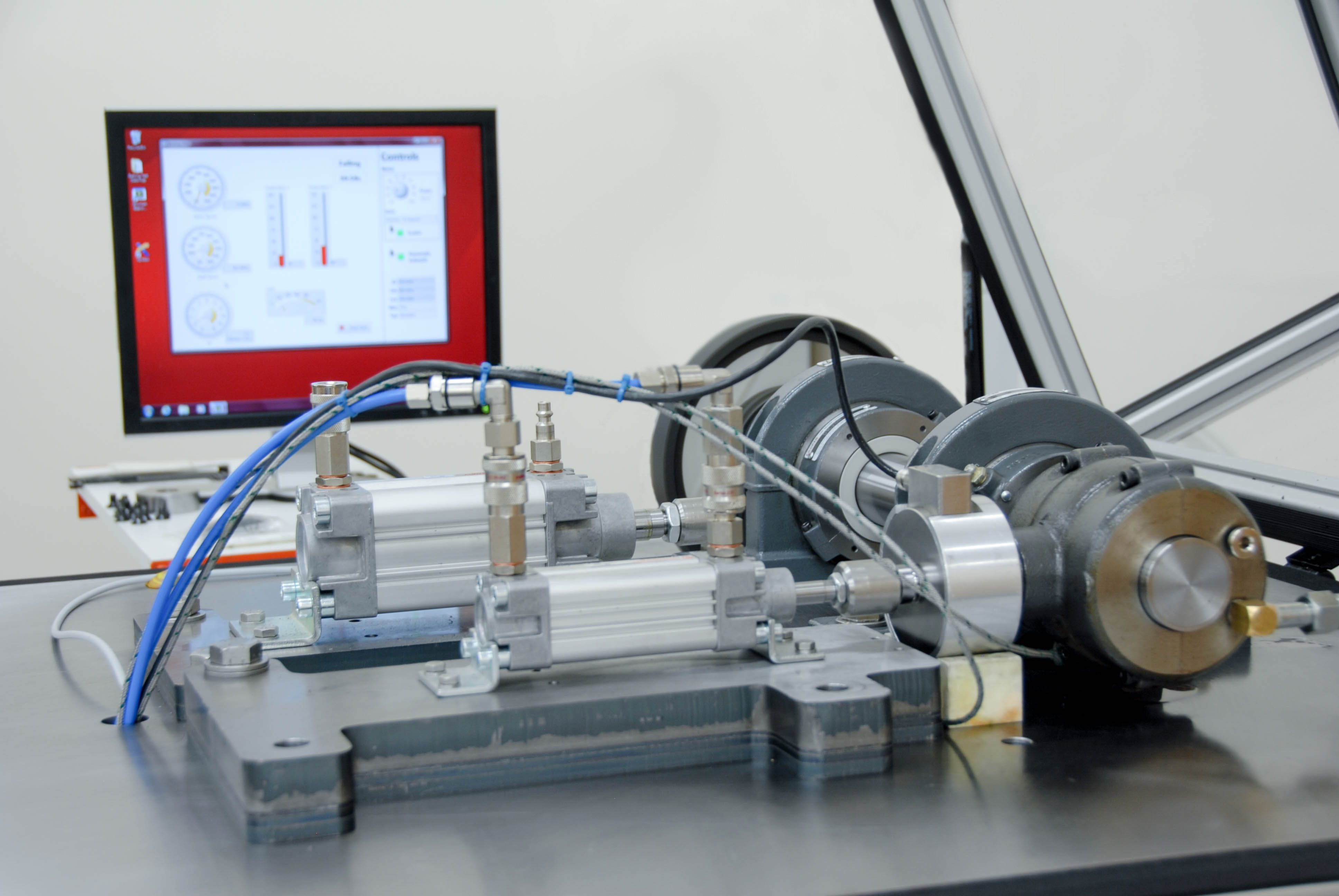

As part of our ongoing dedication to quality products, we have developed our own bespoke bearing test machine, providing an in-house facility that can determine bearing capabilities and provide fault analysis for plain bearings.

This means we are able to test bearings on behalf of our customers under their exact application conditions, with real-time test data, remote computer operation, and a bearing failure onset shutdown function. The machine has been designed to run automatically and can sense the onset of bearing failure, which triggers an automatic stop procedure. This enables the failure mode to be analysed.

We are able to test products dry and lubricated and accommodate a wide range of shaft diameters. We are also able to constantly gather data on test bearing temperature and torque measurement.

Our testing facilities are perfect for advising engineers when they may be unsure of the best solution and for validating material selection prior to production. We can now give our customers the peace of mind that they know for sure that the bearing they have selected has been tested in their specific application conditions. It removes, to a large extent, the uncertainty of selecting a bearing for a new project.

Our inspection facility guarantees the quality of each bearing that leaves our premises. Using the latest technologies, we rigorously inspect each product in the most minute detail to ensure all measurements and dimensions are correct.